Industry 4.0, ERP — Multi Component Painting Machine integration

Realized for Sampierana SPA in collaboration with IT and Production departments:

with support of Anest-Iwata Italy:

and A.S. Divisione Verniciatura.

Introduction

The goal of this project was to realize a middleware with the ability to “simultaneously” drive the mixer and, with actual data collected from the device, feeds ERP production flow.

Components of the solution

The Mixer

Main purpose of this kind of machines is to mix one or more paint with relative hardener in the proportion stated in a recipe in order to produce a pressure controlled flow to the spray gun:

Other than that is important to say that the machine has the ability to keep the last part of the hydraulic circuit clean, as it is a dead end and the painting will solidify when not in use.

The device we will use contain hardware logic that allow control and monitoring from external systems via network connection.

The protocol implemented is Modbus/TCP.

ERP system

The ERP product in use is an Oracle based Italian solution named Freeway® Skyline:

Developed by Eurosystem SPA Treviso (TV)

The middleware

The middleware is a Xamarin/C# mobile application:

this application contain the function we are interested in:

that is divided in 3 sections, the monitoring one:

where you read real time information like:

- device powered on;

- device enabled;

- device painting;

- device cleaning;

- device charging;

- device in alarm;

- painting consumption;

- hardener consumption;

- ERP accumulator for painting consumption (for example if the painting operation is carried out in two phases that the first phase consumption number are stored in the accumulator inside the ERP system and finally summarized with second phase number);

- ERP accumulator for hardener;

- recipe;

- max time remaining before cleaning (if you stop painting the mixture in the last part of the hydraulic circuit start solidifying, you have this time to restart painting or cleaning, otherwise the device alarm is automatically turned on)

the second section is related to connecting ERP documents (in this case production orders) to the physical operation carried out by the machine:

In this part, application let the operator specify the production order operation the machine is going to do. Moreover there are locations to specify quantity and recipe.

The last is the command section, where application issues command to the machine:

Here we have:

- Start;

- Pause (stop the machine but no ERP operation is carried out, only quantities consumed are moved to the accumulators);

- Stop (stop the machine and step over production order operation);

- Clean the hydraulic circuit.

Let’s see how all these systems performs together

First of all when when you start the app you need to select the device and the circuit inside the device (here we have one device with two circuits):

after that you start seeing the status of the device:

what you see is a device enabled in idle state, the number you see relate to the preceding operation and will be reset before starting the new one

At this time you need to tell the system:

- the production order the machine is going to work on (this is done via barcode reader);

- the quantity;

- the recipe.

Done that is time to press the start button:

The software start applying the command asking also for some confirmation, below there is a clip explaining that:

At this point the machine start loading paint and hardener, flushing water and solvent from the last part of the hydraulic circuit (the one that need to be kept clean), the software show that:

And this is what happen in practice:

And now effective painting operation take place, the app signal that:

and start counting the paint and hardener quantities:

of course I cannot show how the effective painting is carried out as it is intellectual property of Sampierana SPA.

In our example these are numbers at the end:

and these are numbers recorded into ERP system, primer (primer is the first paint you apply on the raw material surface):

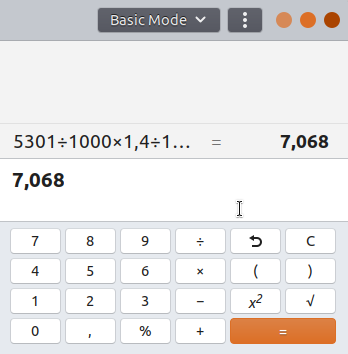

and this is the calculation implemented in software based on product’s density, and water added:

hardener:

and the relative calculation:

Conclusion

In this article we see a middleware implementation for Android Smartphone able to drive an industrial machine while feeding ERP production flow with real data obtained from the device.

That’s an example of what it’s possible to do when an industrial machine is networked and contain logic that enable remote monitoring and controlling via general purpose external software.